Introduction

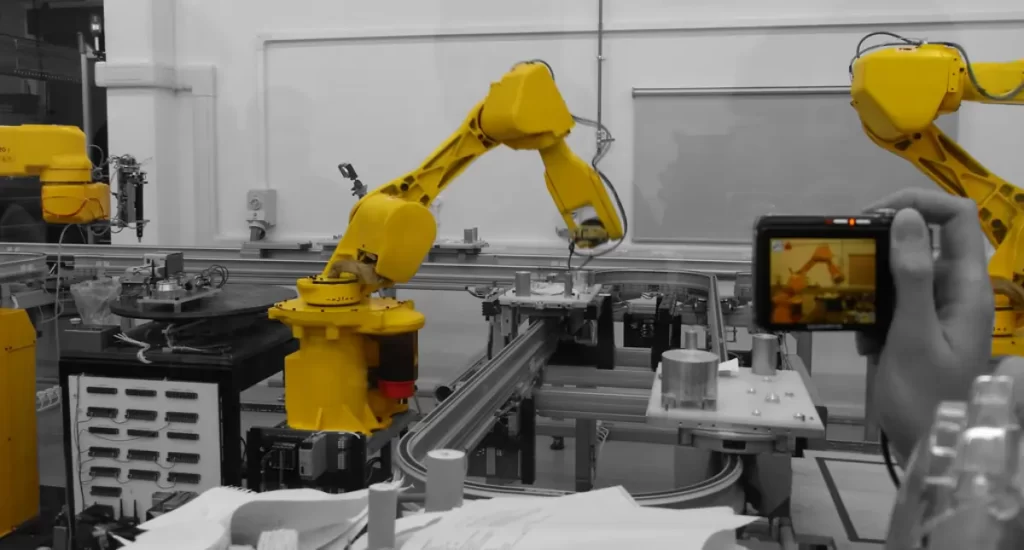

The integration of robotics in manufacturing processes has revolutionized the way products are made. Automated manufacturing, powered by robotics, has emerged as a game-changer, bringing unprecedented efficiency and precision to the production floor. In this article, we’ll explore the impact of robotics in manufacturing, highlighting the benefits, challenges, and the future of automated manufacturing.

Understanding Automated Manufacturing

Automated manufacturing, often synonymous with industrial automation, refers to the use of control systems, machinery, and information technologies to handle different processes in manufacturing. At its core, this approach seeks to minimize human intervention in repetitive, mundane, and often hazardous tasks, replacing or augmenting human labor with robotic systems. Furthermore the aim is to enhance overall efficiency, precision, and productivity within the manufacturing ecosystem.

Key Components

Robotics Integration: The crux of automated manufacturing lies in the seamless integration of robotic systems. The robots are equipped with sensors, actuators, and sophisticated control mechanisms, and they can perform a diverse array of tasks with precision and repeatability.

Control Systems: Automated manufacturing relies heavily on control systems that govern and orchestrate the operation of robotic components. These systems can be programmed to execute tasks with incredible accuracy, and this will ensure that each step of the manufacturing process is synchronized.

Information Technologies: The incorporation of advanced information technologies, such as data analytics and real-time monitoring plays a pivotal role in automated manufacturing. These technologies enable manufacturers to gather insights into the production process, identify bottlenecks, and make data-driven decisions for continuous improvement.

Operational Dynamics

1. Task Automation: Automated manufacturing excels in automating repetitive and time-consuming tasks. These tasks, ranging from assembly line processes to quality control inspections, are handled by robotic systems with a level of speed and precision unattainable by manual labor.

2. Continuous Operation: Unlike human workers who require breaks and adhere to strict working hours, robotic systems can operate continuously. This 24/7 operational capability significantly reduces production times, leading to increased overall output and efficiency.

3. Adaptability: Automated manufacturing systems are designed to be adaptable to changing production requirements. Through programming and reconfiguration, these systems can seamlessly transition from producing one product to another, thereby providing manufacturers with a level of flexibility crucial in dynamic markets.

4. Quality Assurance: The precision of robotic systems ensures a high level of quality assurance. Products manufactured through automated processes are consistent and adhere to strict quality standards, minimizing defects and variations commonly associated with manual labor.

Benefits of Automated Manufacturing

Increased Efficiency: One of the primary advantages of automated manufacturing is the significant boost in efficiency. Robots can work tirelessly 24/7, reducing production times and increasing output.

Precision and Consistency: Robots excel in executing tasks with unparalleled precision and consistency. This ensures that each product meets the same high-quality standards, eliminating variations caused by human error.

Cost Savings: While the initial investment in robotic systems can be substantial, the long-term cost savings are substantial. Robots can operate continuously without breaks or vacations, reducing labor costs and increasing overall production efficiency.

Improved Safety: Dangerous and repetitive tasks can be delegated to robots, thereby minimizing the risk of accidents and injuries in the workplace. Equally important to note that this not only protects human workers but also contributes to a safer working environment.

Flexibility and Adaptability: Automated manufacturing systems are designed to be flexible and easily adaptable to changes in production requirements. This agility allows manufacturers to respond quickly to market demands and optimize their production processes.

Challenges in Implementing Automated Manufacturing

High Initial Costs

The upfront costs associated with implementing automated manufacturing systems can be a barrier for some businesses. However, it’s crucial to view this as a long-term investment with substantial returns.

Integration Complexity: Integrating robotics into existing manufacturing processes can be complex. It requires careful planning and coordination to ensure a seamless transition without disrupting ongoing operations.

Job Displacement Concerns

The widespread adoption of robotics has sparked concerns about job displacement. While it’s true that certain manual tasks may be automated, the overall impact on employment is more nuanced. Automation often leads to the creation of new, more skilled jobs in the industry.

Maintenance Challenges

Robotic systems require regular maintenance to ensure optimal performance. Manufacturers need to invest in training and maintenance programs to address technical issues promptly.

The Future of Automated Manufacturing

As technology continues to advance, the future of automated manufacturing looks promising. Here are some trends and developments to watch for:

1. AI Integration

Artificial intelligence is increasingly being integrated into robotic systems, allowing them to learn and adapt to changing conditions. This enhances their decision-making capabilities and further improves efficiency.

2. Collaborative Robots (Cobots)

The rise of collaborative robots, or cobots, is transforming the manufacturing landscape. These robots can work alongside human operators, enhancing productivity and promoting a collaborative working environment.

3. IoT Connectivity

The Internet of Things (IoT) is playing a crucial role in connecting robotic systems and facilitating data exchange. This connectivity enables real-time monitoring, predictive maintenance, and enhanced overall performance.

4. Customization and Small-Batch Production

Automated manufacturing is becoming more adept at handling customization and small-batch production. This flexibility allows manufacturers to meet the growing demand for personalized products.

Conclusion

Automated manufacturing, fueled by the power of robotics, is reshaping the landscape of the manufacturing industry. The benefits of increased efficiency, precision, and adaptability far outweigh the challenges. As technology continues to evolve, the integration of robotics into manufacturing processes is becoming more sophisticated, unlocking new possibilities and transforming the way products are made. Embracing these technological advancements is not just a choice but a necessity for staying competitive in the dynamic world of manufacturing.